CNC turning and metalworking at Veenstra Technology

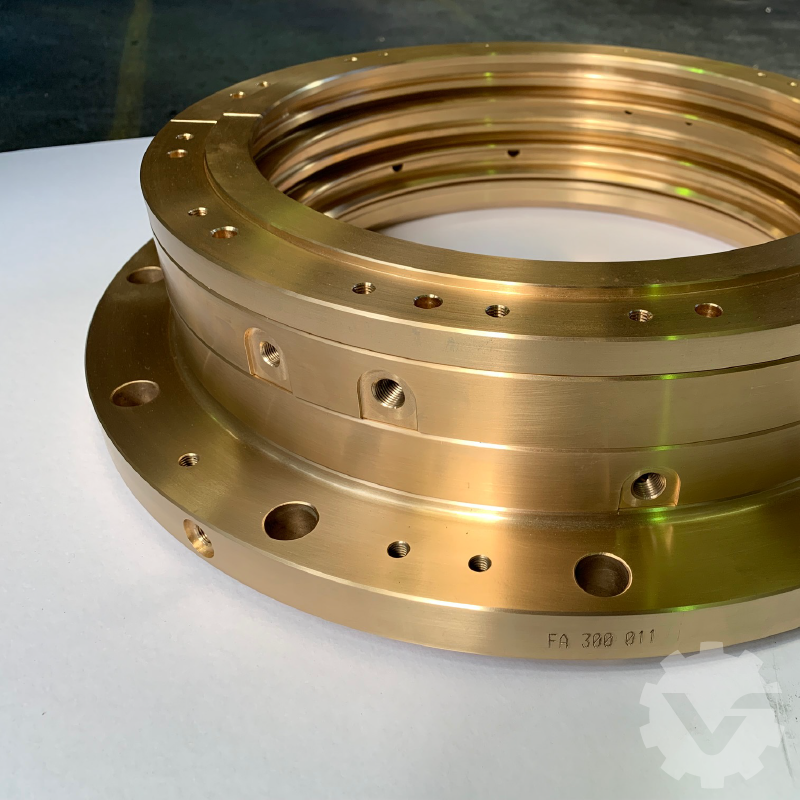

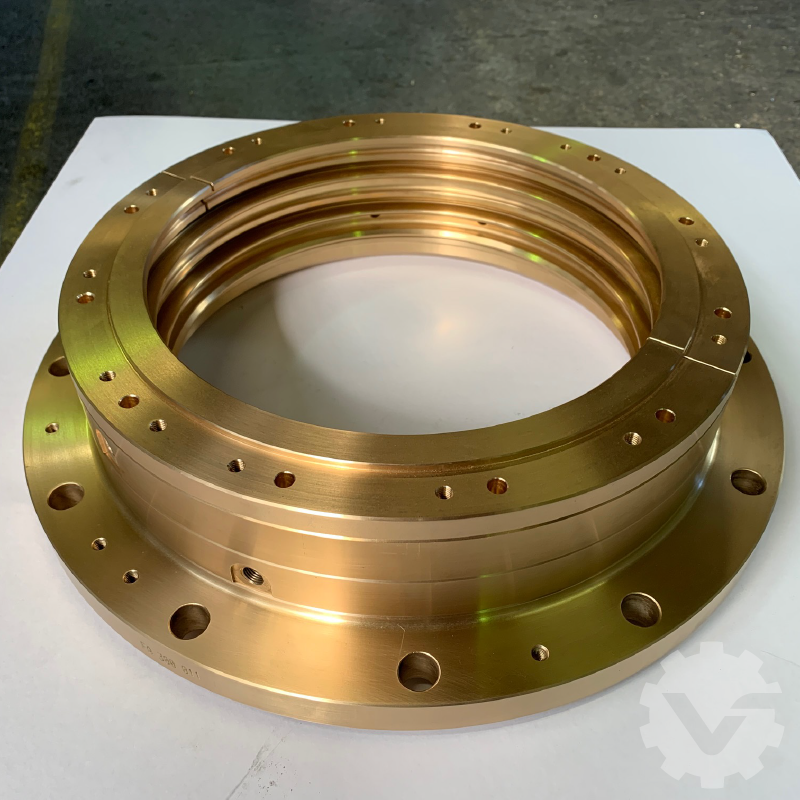

Metalworking is a highly specialised technique for processing metals to create new structures and shapes. Metal products are used in all sorts of industries, from demanding industries such as mechanical engineering to the medical and food industries. Each production process requires its own, tailor-made machines to make the process run as smoothly as possible.

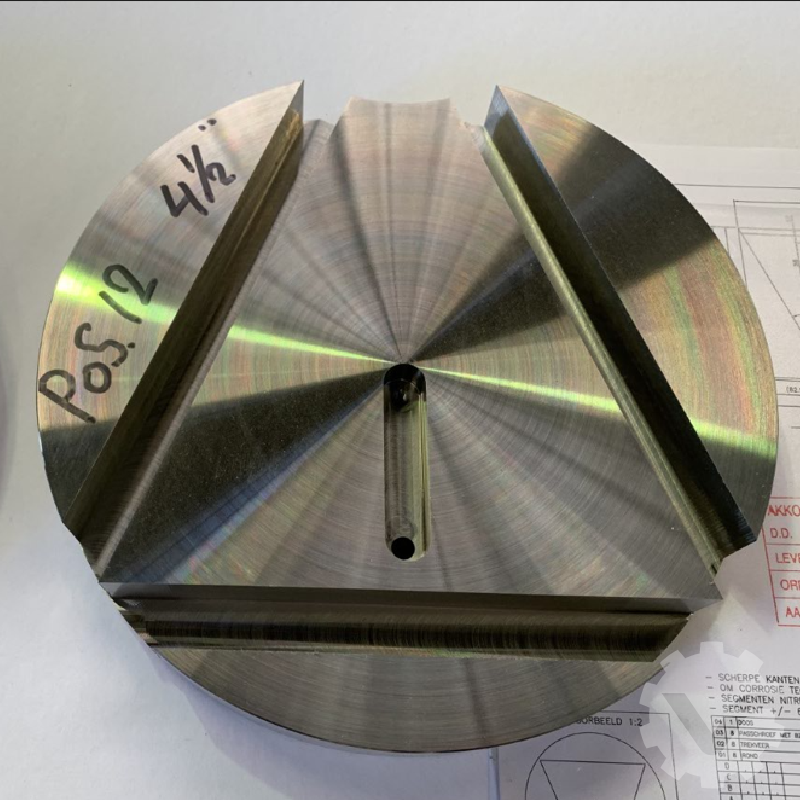

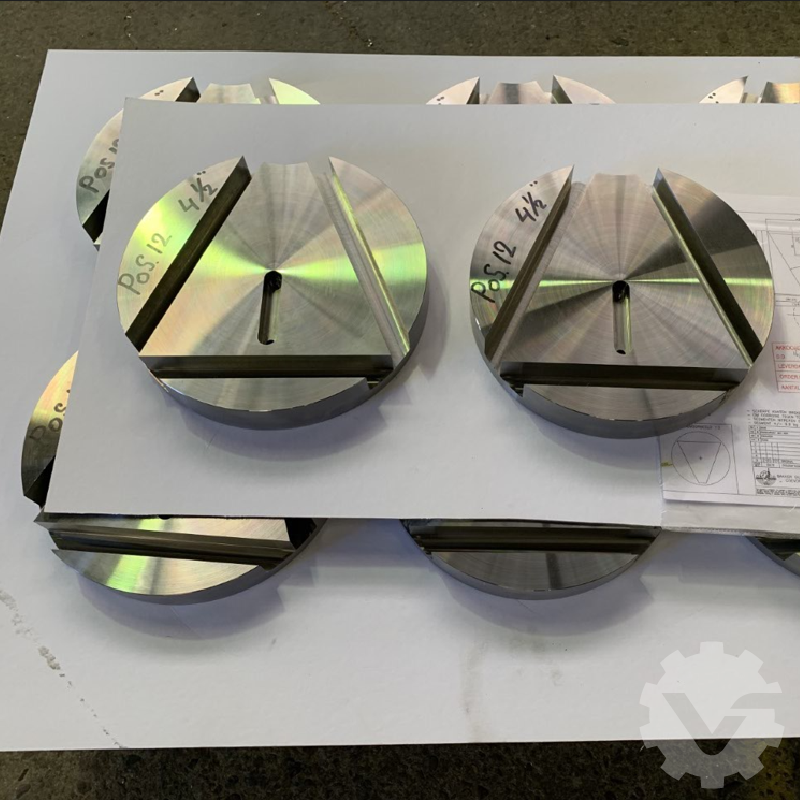

Using various forms of metalworking, such as CNC turning and CNC milling, we can help you customise (parts for) your heavy machinery. One of the techniques we use in metalworking is CNC turning. CNC turning is a machining technique that can be used to produce metal in any desired shape.

How does CNC turning work?

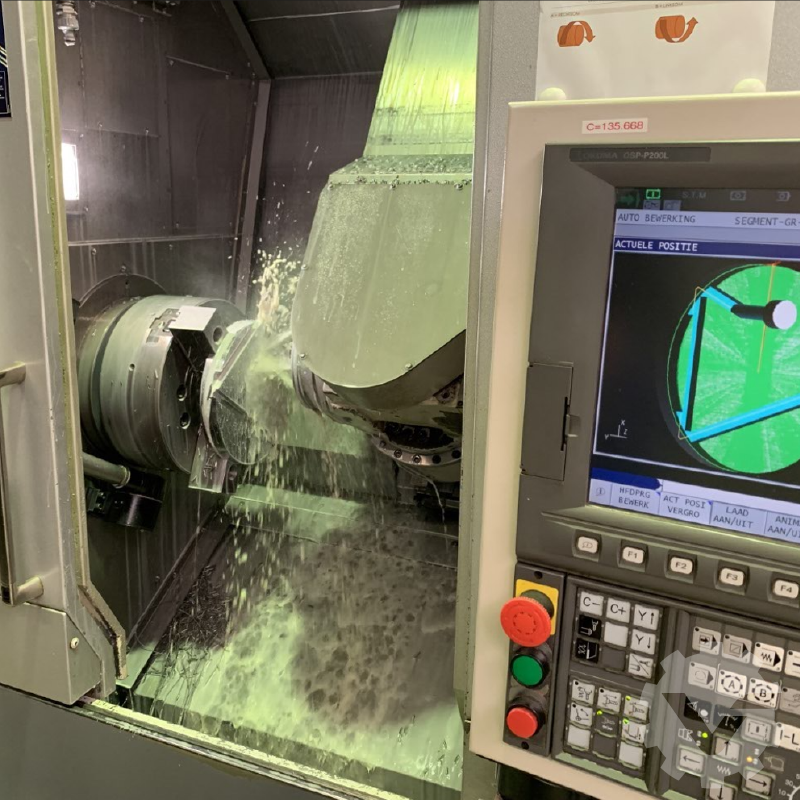

CNC turning is a machining technique for processing metal and other materials. With machining, parts of a material are removed by shearing, creating “chips” (curls). In this way the material is formed into the desired shape. In CNC turning, the product that is to be manufactured rotates on a special lathe, while the cutting movement is performed by a chisel.

CNC stands for Computer Numerical Control. This means that computer-controlled machines perform the actions and take care of the machining. The great advantage is that the process is automated and can be repeated. This makes CNC turning particularly suitable for producing larger batches.

CNC turning is mainly used in metalworking, but it can also be used to shape other materials. It can also be used for machining materials like wood and plastic.

Implementing CNC turning for your products

The machines that we use for CNC turning can perform various turning operations. These include longitudinal turning, cross turning, profile turning, thread cutting and taper turning. Because practically all turning operations are possible with this form of metalworking, we can produce your products very accurately and in any desired shape.

Our specialists are happy to discuss your requirements with you. They will consult with you and think along with you about the solutions to your challenges. We have our own production facility, which means we are very flexible and can always produce a customised solution for you.

In addition to CNC turning, we are specialised in various other forms of metalworking:

Would you like to know more about CNC turning?

Veenstra Technology has over 100 years of experience in metalworking. The company’s predecessor was founded in 1921 as a forge and through the years we have developed into one of the specialists in the field of metalworking, agitators, bulk loading, machine construction and various other industrial operations.

Would you like to know more about CNC turning at Veenstra Technology, our way of working or do you have any other questions? Fill in the contact form or contact us directly.