Veenstra Technology is the supplier of fluidisation systems

The swift and accurate transfer of bulk goods from silos to trucks, railway wagons or other means of transport requires precision. Veenstra Technology is your partner for efficient and reliable bulk loading systems and products, such as fluidisation systems. In our own production facility we are designing and producing comprehensive systems for optimising the handling of bulk goods. Because we do design and build the products ourselves, we can think along with you about a custom solution. Do not hesitate to contact us to discuss your requirements and the possibilities with our engineers.

Fluidisation systems ensure an optimal outflow from your silos

A common problem in silos is the so-called bridging of the product. In a silo, it can occurn that product residues accumulate against the silo wall: a ‘bridge’. This obstructs the flow of goods out of the silo. Because these bridges are often removed by hitting the silo with a hammer, the silo wall is often damaged.

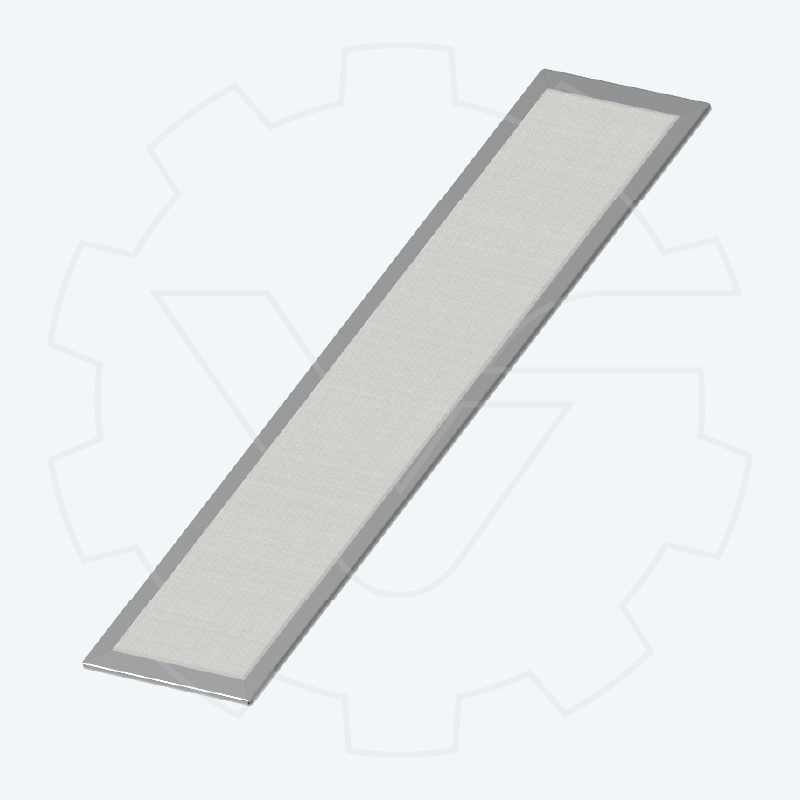

By installing a fluidisation system in the silo, bridging is prevented. We do offer several types of fluidisation systems: fluidisation pads and fluidising bottoms. These systems allow the silo to be aerated and prevent the cohesion of the product in the silo. This allows the contents of the silo to flow out properly.

Installing a fluidisation pad

The installation of a fluidisation pad in the silo is something that can be done by yourself. The installation basically consists of these 4 steps:

- Drill holes in the silo – at the right location

- Place the pads

- Fasten them with a seal, a wash-ring and a nut

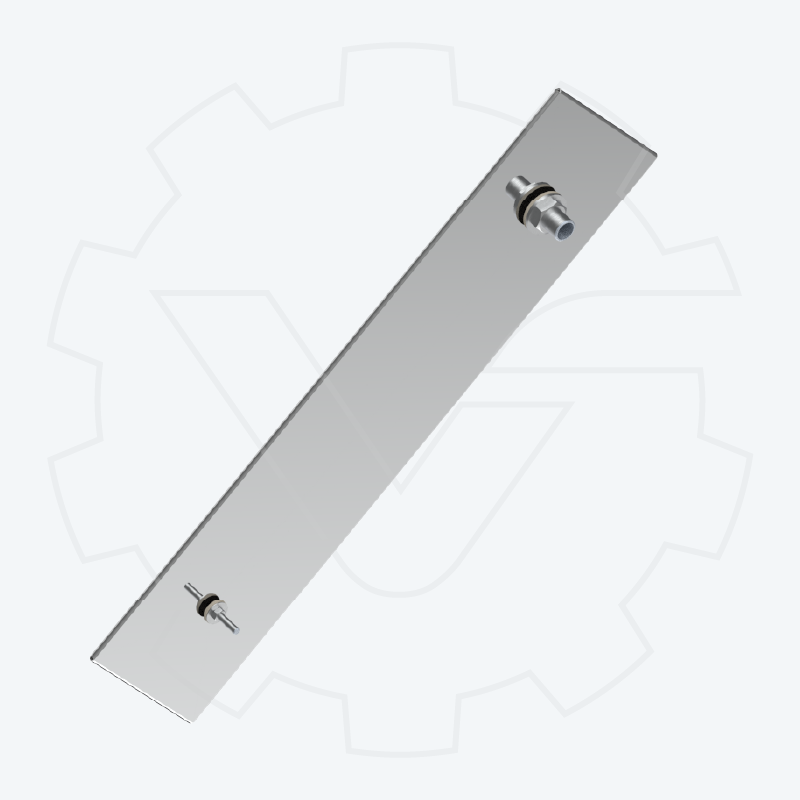

- Connect the pad(s) to an air manifold

The air manifold/circuit line is connected to the pads and provides a constant flow of air trough the fluidisation pads. Do you have questions about the installation, or would you rather leave it to our professionals? If so, please contact us.

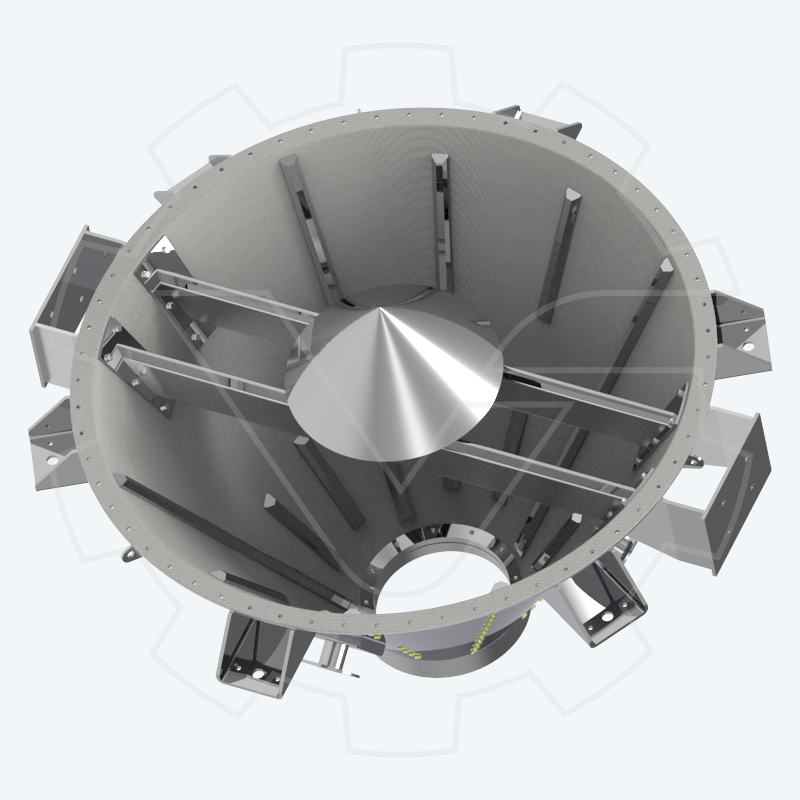

Customised fluidising bottoms

A fluidising bottom is a custom-made solution that ensures that there is no accumulation (“bridging”) of a product inside the silo. These bottoms ensure that the product is fluidised over the entire cone, by means of aeration. Because every silo and loading process is different, we are producing these fluidising bottoms to order. Would you like to know more about our fluidising bottoms? Do not hesitate to get in touch with us. Our engineers are willing to provide you with advice on the best solution for your loading process.

An indispensable part of any bulk system

A complete bulk loading system consists of different components, which need to fit together seamlessly. By applying the loading process as efficiently as possible, loss of goods is prevented due to, for example, dust. During the transfer of the goods also valuable time is saved, when all the components are properly coordinated. We do supply fluidisation systems for all kinds of goods, including food products such as cocoa and flour, and more industrial products such as cement and silica. Our fluidisation systems are suitable for application in food processing environments.

In addition to fluidisation systems, we ar developing and manufacturing other products in the bulk loading process, including:

Want to know more about our fluidisation systems?

In addition to bulk loading systems, we are pioneers in agitators, metalworking and machine construction. Do you have questions about how your bulk loading process can be optimised using a fluidisation system? Get in touch with us.

Veenstra is a pioneer in the application of fluidisation techniques and has the knowledge and rapid testing options with which we can determine the ideal distribution of the pads in your silo. Feel free to contact us to discuss the options available for your silos.