Agitator for sludge buffer tank

For the biological expansion of the sewage treatment plant (RWZI) in Kampen, the ‘Drents Overijsselse Delta’ Water Board has contracted out the design and implementation of the sludge buffer tank to the ‘Water Techniek Twente’ engineering firm. Veenstra Technology was asked for the technical elaboration and realization of the agitator for the sludge buffer tank. The complete design, production and installation on location has been done by Veenstra.

Read more

Background

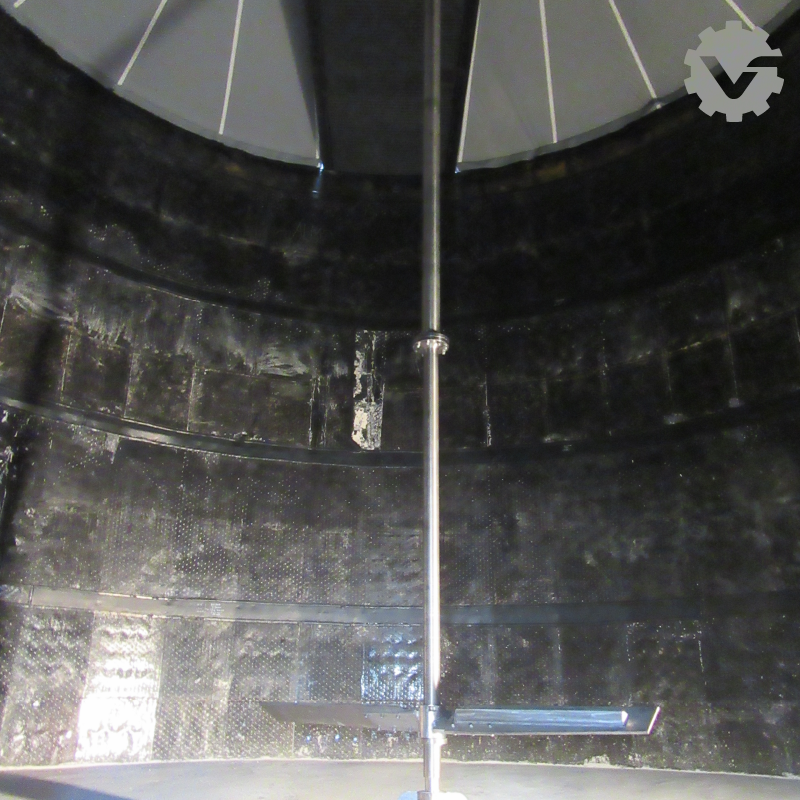

During the purification of waste water sludge is released. Before this sludge was digested at the Kampen sewage treatment plant. For efficiency reasons, sludge digestion no longer takes place in Kampen. From 2018, this sludge is temporarily stored in the new sludge buffer tank and then processed at the water treatment plant in Zwolle. The thickened sludge inside the buffer tank of Kampen is kept homogeneous by the Top-Entry agitator from Veenstra Technology. This buffer tank has a diameter of 10 meters and a height of 8 meters.

Scope of delivery

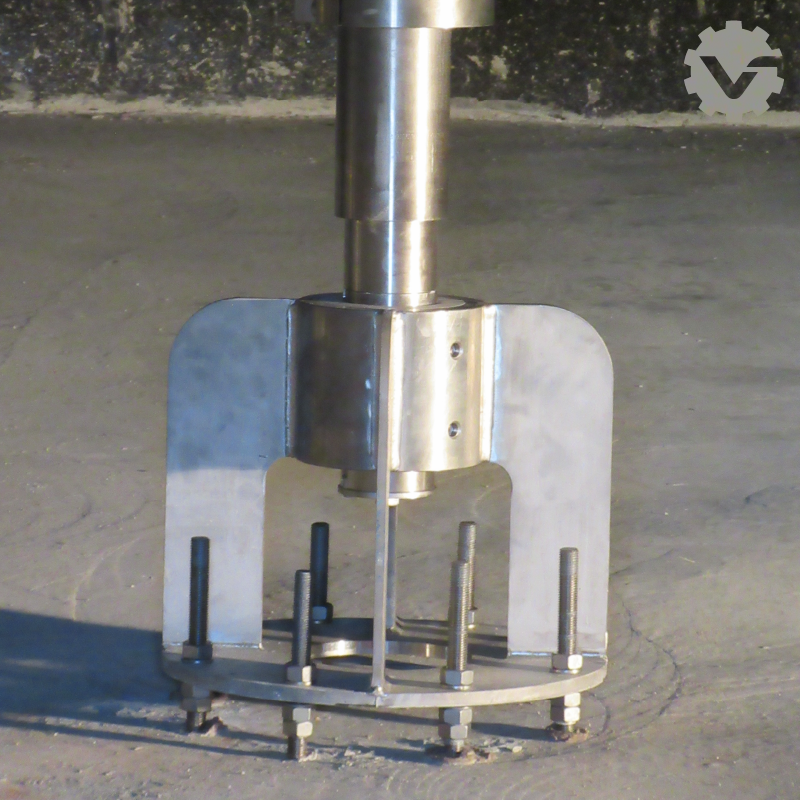

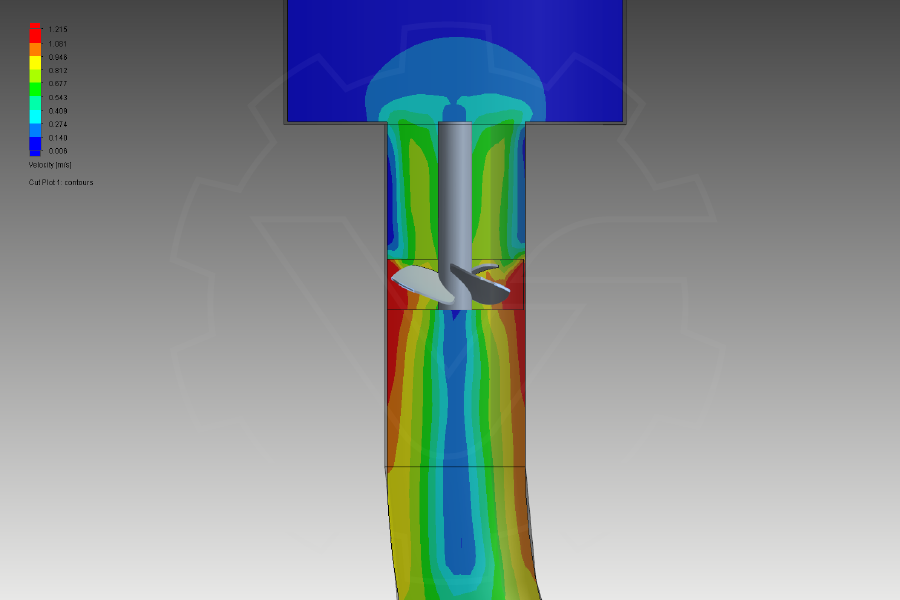

The Top-Entry agitator supplied by Veenstra consists of a 15kW motor with gearbox, a double bearing housing, a coupled agitator shaft, a bottom bearing and a 2-blade skew-blade rudder body with a diameter of 2.9 meters.